Have you ever wondered how those massive industrial facilities generate so much power? A significant portion of that energy often comes from coal, a readily available and relatively inexpensive fuel source. Understanding the intricacies ofhow coal energy is made in industrial facilitiesis crucial for comprehending the energy landscape and its environmental implications. This post will guide you through the process, highlighting the significance ofcoal power generation, the advancements incoal combustion technologies, and the challenges surroundingcoal-fired power plants. Let's explore the journey of coal from a mined resource to a source of electricity that powers our world, offering valuable insights into this cornerstone of industrial energy production and discussing various methods likepulverized coal combustion.

All About How Coal Energy Is Made in Industrial Facilities

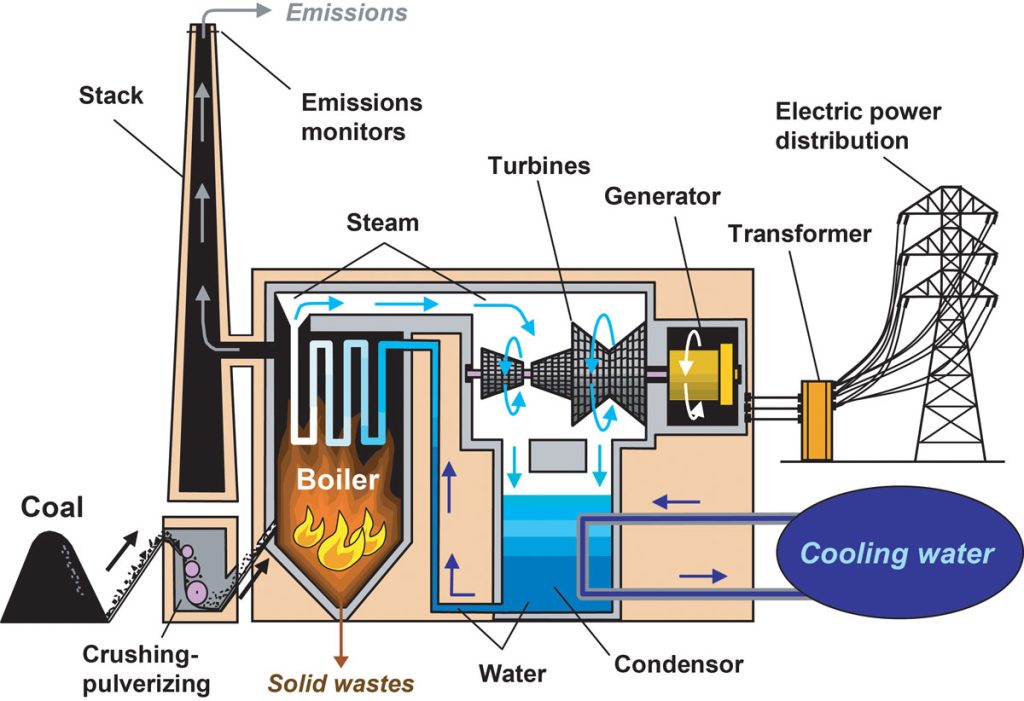

Coal energy generation in industrial facilities is a multifaceted process that hinges on the fundamental principle of converting the chemical energy stored in coal into thermal energy, and then into electrical energy. Essentially,coal is burned to produce heat, which is then used to create steam. This high-pressure steam turns turbines connected to generators, ultimately producing electricity. The simplicity of this concept belies the complex engineering and operational considerations involved in making it work efficiently and safely.

The historical background of coal energy is deeply intertwined with the Industrial Revolution. As early as the 18th century, coal began replacing wood as the primary fuel source for steam engines. The 20th century saw significant advancements in coal combustion technologies, leading to larger and more efficient power plants. Today,coal-fired power plants remain a significant source of electricityglobally, although their role is decreasing in some regions due to environmental concerns and the rise of renewable energy sources.

What sets coal energy apart from other energy sources is its relative abundance and accessibility in many parts of the world. Coal reserves are more evenly distributed than oil or natural gas, making it a strategically important resource for energy security in some countries. Furthermore, the technology for coal power generation is well-established and relatively inexpensive compared to some emerging renewable technologies. However, coal power generation is also characterized by its high carbon emissions and environmental impact, prompting research into cleaner coal technologies like carbon capture and storage. Industry experts recognize the need to balance energy needs with environmental stewardship, leading to ongoing discussions about the future of coal in a sustainable energy mix.

Benefits of How Coal Energy Is Made in Industrial Facilities for Users

While not directly benefiting individual users in the same way as, say, a solar panel installation on your roof, coal energy indirectly enhances the user experience by providing a reliable and affordable source of electricity that powers homes, businesses, and industries. This reliable power grid is crucial for modern life, powering everything from our lights and appliances to our computers and communication networks.

Real-life examples of the benefits are evident everywhere. Consider a hospital that relies on a stable electricity supply to operate life-saving equipment, or a manufacturing plant that needs a consistent power source to maintain production. In both cases, coal-fired power plants contribute to the reliability of the grid, ensuring these essential services can continue to function.

When compared with alternative technologies, coal energy offers the advantage of consistent power generation, unaffected by weather conditions like solar or wind power. Coal plants can provide a baseload power supply, meaning they can operate continuously to meet the constant demand for electricity. However, this reliability comes at the cost of higher carbon emissions compared to renewable alternatives. Data from organizations like the International Energy Agency (IEA) show that coal is still a significant contributor to global electricity generation, but also highlight the urgent need to transition towards cleaner energy sources to mitigate climate change.

How to Use How Coal Energy Is Made in Industrial Facilities

It's important to clarify that "using" how coal energy is made isn't something an individual user directly controls. It's a complex industrial process managed by power plant operators and engineers. However, understanding the steps involved helps appreciate the scope and implications of this energy source.

1. Mining and Preparation

The first step involves extracting coal from the earth, either through surface mining or underground mining. Once mined, the coal undergoes preparation processes, including crushing, washing, and sorting to remove impurities and ensure consistent quality. This preparation is crucial for efficient combustion and reducing emissions.

Best practicesinclude proper dust control to minimize air pollution and efficient transportation methods to reduce energy consumption.

2. Combustion

The prepared coal is then fed into a boiler, where it is burned in a controlled environment. There are differentcoal combustion technologies, includingpulverized coal combustion (PCC),fluidized bed combustion (FBC), andintegrated gasification combined cycle (IGCC). PCC is the most common, where coal is ground into a fine powder and blown into the boiler.

Common mistakes to avoidinclude incomplete combustion, which leads to higher emissions of pollutants like carbon monoxide and particulate matter.

3. Steam Generation and Electricity Production

The heat from the burning coal boils water, creating high-pressure steam. This steam is then directed to a turbine, which spins due to the force of the steam. The turbine is connected to a generator, which converts the mechanical energy into electrical energy.

Further optimization includes utilizing combined cycle systems for increased efficiency, where waste heat from the combustion process is used to generate additional electricity.

Tips Before Considering Coal Energy as a Solution (Industry Perspective)

While individuals don't directly "use" coal energy, industries considering building or operating coal-fired power plants should adhere to the following guidelines:Preparation: Thoroughly assess the environmental impact and regulatory requirements. Conduct detailed feasibility studies to evaluate the economic viability and technological options. Recommendations: Prioritize cleaner coal technologies, such as FBC or IGCC, to reduce emissions. Invest in advanced emission control systems, including scrubbers and carbon capture technologies. Consequences:Ignoring these tips can lead to significant environmental damage, regulatory penalties, and reputational risks. Failing to adopt cleaner technologies can also result in stranded assets as regulations become stricter and renewable energy becomes more competitive.

Common Issues and Solutions Related to How Coal Energy Is Made in Industrial Facilities

Here are some common issues encountered in coal-fired power plants and their potential solutions: Issue: High Emissions of Pollutants (SO2, NOx, Particulate Matter). Solution: Install advanced emission control systems, such as flue gas desulfurization (FGD) systems for SO2, selective catalytic reduction (SCR) systems for NOx, and electrostatic precipitators (ESPs) for particulate matter. Issue: Greenhouse Gas Emissions (CO2). Solution: Implement carbon capture and storage (CCS) technologies to capture CO2 from the flue gas and store it underground. This is a complex and expensive solution but is crucial for mitigating climate change. Issue: Ash Disposal. Solution: Implement responsible ash management practices, including landfilling or beneficial reuse of ash in construction materials or agriculture. Ensure proper monitoring and containment to prevent groundwater contamination. Issue: Inefficiency. Solution: Regularly maintain and upgrade equipment to improve efficiency. Consider using combined cycle systems or waste heat recovery technologies to extract more energy from the fuel.

Conclusion

Understandinghow coal energy is made in industrial facilitiesis essential for comprehending the global energy landscape and its impact on the environment. While coal offers the advantages of relative abundance and reliable baseload power, it also poses significant environmental challenges. The future of coal energy depends on the development and implementation of cleaner coal technologies and a transition towards more sustainable energy sources. For those considering coal energy solutions, prioritize environmental responsibility, invest in advanced emission control systems, and carefully assess the long-term economic and environmental implications. It's clear that coal will likely continue to playa role in the energy mixfor some time to come, the focus should always be on methods for minimizing its environmental footprint.